Coordinator

SINTEF AS

Project Total Budget

3.988.603,75 €

Turkish Partners

Türkiye Petrol Rafinerileri Anonim Şirketi (TÜPRAŞ)

Desteklendiği Program ve Alan

Climate, Energy and MobilitySupported Framework Program

Horizon 2020

Project Website

http://www.ebio-h2020.eu/Project Summary (Aim and Main Tasks)

Tüpraş is the largest industrial enterprise in Turkey, the 7th largest refinery company in Europe and Turkey's first producer in the oil and gas sector.

Tüpraş keeps improving its sustainability, environmental, social and economic performance every day and carrying out its activities with the motto "We Know the Value of Life".

Tüpraş closely follows global developments, primarily the European Green Deal, for transition to a low carbon economy by evaluating the effects of climate change risks in its business processes. As a responsible producer, Tüpraş continues to work on reducing the use of natural resources, efficient use of resources and recycling wastes in all the processes to reduce environmental and social impacts. Evaluation of the environmental impacts of the projects with a holistic approach through "Life Cycle Analysis" is performed by including the possible carbon pricing in investment projects feasibility studies. As a part of R&D activities, Tüpraş intensively continues its partnerships with world-leading research centers, universities and industrial organizations in the field of CO2 reduction. Following the Horizon 2020 program, the company aims to take part in Horizon Europe with projects on renewable fuels and hydrogen production, as well.

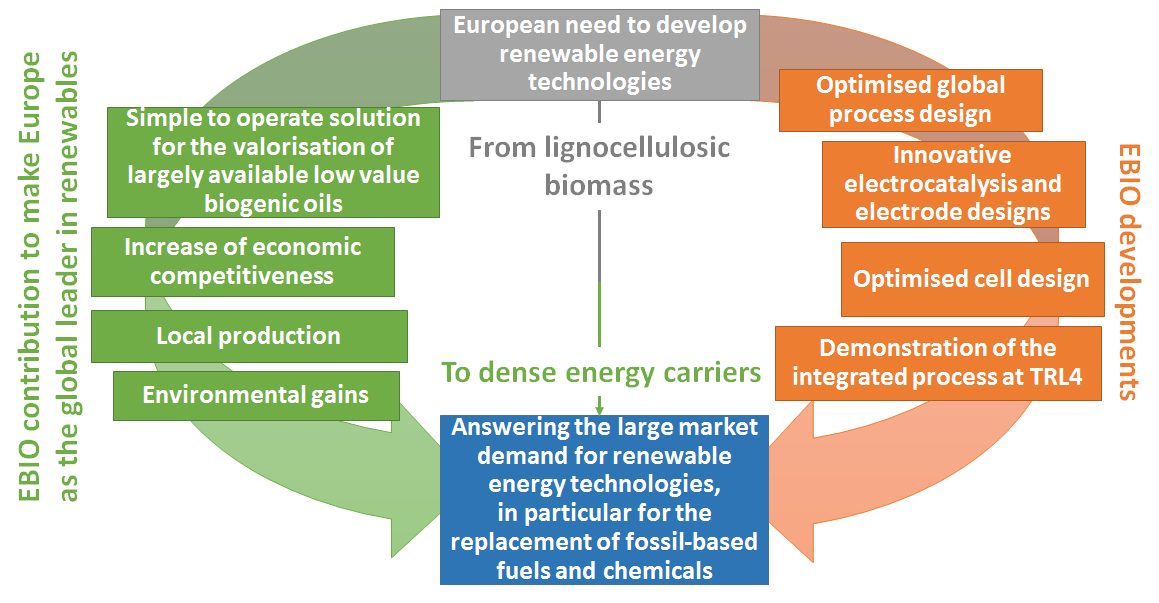

In the following thirty years, forestry residues and industrial lignocellulosic waste will be the widespread feedstock for biofuel production in Europe and in the World. The EBIO project enables the transformation of cost-effective and abundant biomass feedstock into energy dense transport fuels in sustainable and socially acceptable manners. In this scope, pyrolysis oil from waste residue pyrolysis and black liquor from the craft lignin process will be treated with a novel electrochemical method, including reduction and depolymerization reactions, to convert them into suitable feedstock co-processable in petroleum refineries. This sustainable feedstock will be evaluated in laboratory scale fluid catalytic cracking (FCC) and hydroprocessing (hydrotreatment and hydrocracking) units toward the production of petrochemicals and renewable fuels, mainly diesel and jet fuel. The laboratory reactor system will act as the prototype for the industrial scale reactors. Application of the EBIO technology in Europe will provide the reduction of 190 million tons of carbon dioxide emissions and the production of 61 million tons of biofuels each year.

Scientific Output/Product/Earning from the Project

Construction of the laboratory scale electrochemical reactor system, optimization of the electrochemically treated bio-oil co-processing in refinery FCC and hydroprocessing units, and reporting of the final fuel product properties constitute the main output of the project. The main earning will be the decreased greenhouse gas emission in fuel production from the low cost and low carbon technology.

Target Group of the Project

The project addresses to forestry and paper industries as wood chips and black liquor is obtained from these industries to the pyrolysis industry as pyrolysis oil will be produced from wood chips, to the electrode manufacturers as electrochemical reactor system will be used, to petroleum refineries as bio-oils will be processed in the refinery units, to hydrogen production industry as hydrogen is used in bio-oil processing, to the transport fuel industry and the petrochemical industry as the final products include LPG, naphtha, gasoline, jet fuel and diesel.

Importance on Combatting Global Problems

The project serves the greenhouse gas emission saving target from transport fuels (10% in 2020, 14% in 2030) in the scope of the European RED II Directive. Besides, utilization and export of the low carbon transport to the EU will be realized in correspondence with the Carbon Border Adjustment Mechanism of the EU Green Deal. Tüpraş will be advancing in the field of the United Nations Sustainable Development Goals following as Industry, Innovation and Infrastructure, Responsible Production and Consumption, Climate Action, and Partnerships for the Goals.

Scientific/Social/Economic/Innovative Contribution

The innovative side of the project is the novel electrochemical method enabling the utilization of the difficult-to-handle feedstock, namely the pyrolysis oil and black liquor, in petroleum refinery units. Extensive scientific and R&D work will be necessary for the development of the electrochemical upgrading system and for the optimization of the bio-oil co-processing operation conditions in the laboratory scale FCC and hydroprocessing reactors. An important social contribution will be the support to the food security, as the feedstock of the project is not in competition with the food and feed industries. New employment opportunities may arise by the installation of electrochemical upgrading and pyrolysis plants. Besides, the utilization of renewable electricity in electrochemical upgrading will reduce the carbon footprint of the transport fuel life cycle, thus combatting with the climate change. The economic value will arise from the conversion of low cost biomass-based waste into energy fuels and the decreased dependency on fossil fuels.

Contribution to the Development of Professional Skills

Local and international engineers, technicians and doctorate students and academicians are working together on the project from a multidisciplinary point of view. Various fields nourish the project including biology, chemistry, electrochemistry, chemical engineering, reaction engineering, catalysis, fuel analysis, process design, economic analysis, life cycle analysis, project management and graphical design. Periodic meetings will be hold with the participation of all partners for discussing the ideas, presenting the outcomes, visiting laboratory and plant sites, attending workshops. Tüpraş is a work package leader in the project and will be in close contact with the Spanish National Research Council for the implementation of the project outcomes in refineries. Tüpraş will be following the waste to fuels value chain and the corresponding new technologies.

Contribution to Human Resource Development

Scientists and engineers globally are thriving to develop low carbon fuel production technologies from the sustainable second-generation feedstock such as forestry and paper industry residues. Considering the scarcity of the biofuel experts in our country, training of the new experts in biofuel production technologies is crucial in terms of our energy security. New professionals will grow during the project who will be capable of understanding the renewable fuel production steps and the life cycle of renewable fuels. Those professionals will then be available to training new students and engineers in the upcoming funded projects.

Project Partners

The project consortium consists of nine organizations from seven different countries. The coordinator is Sintef / Norway. The consortium partners beside Tüpraş are, B.T.G. Biomass Technology Group / Netherlands, Johannes Gutenberg-Universität Mainz / Germany, Universiteit Twente / Netherlands, Condias GmbH / Germany, Poyry / Sweden, ETA / Italy and El Consejo Superior de Investigaciones Científicas (CSIC) / Spain.