Coordinator

LEITAT Technological Center

Project Total Budget

13,212,811 Euro

Turkish Partners

Ford Otosan

Desteklendiği Program ve Alan

Digital, Industry and SpaceSupported Framework Program

Horizon Europe Programme: HORIZON-CL4-2021-RESILIENCE-01-04: Developing climate-neutral and circular raw materials (IA)

Project's CORDIS Link

https://cordis.europa.eu/project/id/101058359Project Website

https://batraw.eu/Summary of the project

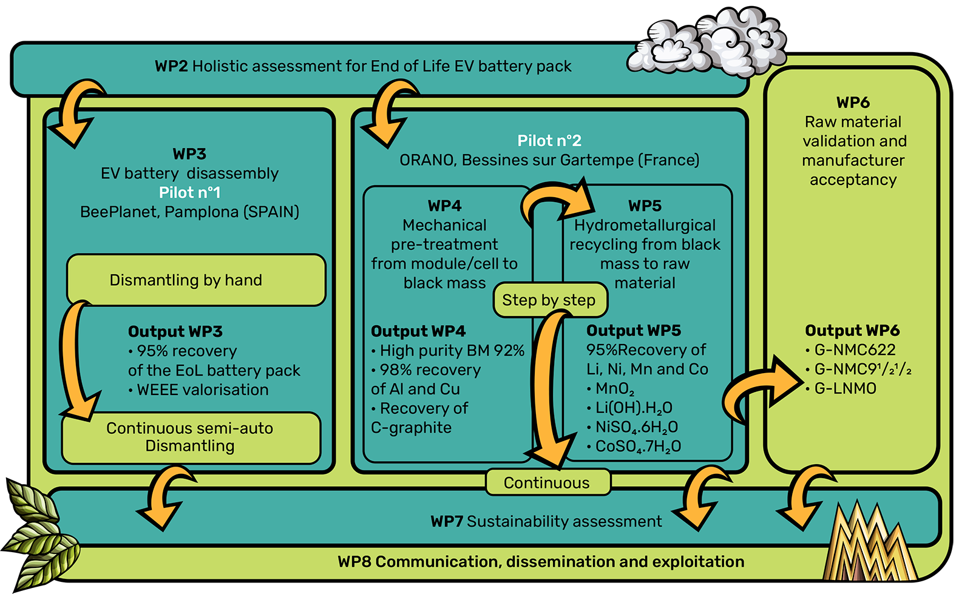

BATRAW develops new processes for battery repair and reuse, ensuring sustainability and circularity of batteries and raw materials, faster diagnosis of electric vehicle battery packs. In this regard, project establishes sustainable recycling and end-of-life models for batteries.

The project aims to recover valuable metals (Co, Ni, Mn, Li, C-graphite, Al and Cu) from end-of-life electric vehicle and domestic batteries with high efficiencies through newly developed semi-automated systems. A new cathode will be produced from recycled raw materials and compared with conventional cathodes in terms of performance, economics and environmental impact. Within the scope of the project, it is intended to create a prototype for the secondary life of batteries, to publish an eco-design guide targeting battery design, to implement a battery passport platform for raw material tracking and supply chain transparency, to provide guidelines for the safe transport and handling of battery waste, and to conduct a Life Cycle Analysis study of the processes carried out within the scope of the project. It will also contribute to policies and standards on raw materials, battery processing, recycling and waste.

Scientific Output/Outcome Expected From the Project

- Faster pack characterisation and higher efficiency in pack, module and cell disassembly

- Battery recycling with higher efficiencies

- Reuse of recycled Cobalt, Lithium, Nickel, Manganese, etc. and cathode production

- The cathode produced from recycled materials achieves the performance of the cathode produced from primary elements and costs are reduced to <30 €/kWh.

- Ensuring the traceability of the entire battery value chain with block chain technology

- Secondary life application of scrap batteries

- Establishing eco-design guidelines and facilitating the production of modular battery packs that can be more easily repaired and disassembled.

- Establishing safe and proper procedures for the disposal and transport of waste batteries

- Performing a Life Cycle Assessment (LCA) of the processes carried out within the scope of the project and providing an analysis of the environmental impact of the secondary life cycle applications.

Target Group of the Project

- Automotive manufacturers

- Battery manufacturers

- Energy companies

- Raw material producers

- Battery recycling plants

Importance of the project in Tackling Global Challenges

- The number of end-of-life batteries is growing rapidly with the increasing number of electric vehicles. The precious metals in batteries and the 70-80% remaining capacity in end-of-life batteries create an opportunity for secondary use. BATRAW prevents the generation of waste by offering the opportunity for secondary use of batteries. At the same time, BATRAW develops recycling technologies with high efficiencies that can respond to the increasing market demand for critical raw materials. For batteries, which are carbon-intensive components, these developments create environmentally friendly alternatives.

- BATRAW supports the circular economy of batteries through the Battery Passport, which provides raw material and product traceability by ensuring transparency in the supply chain. It also serves the circular economy by publishing an eco-design guide focused on battery design, which provides recommendations to facilitate battery disassembly, repair and reuse.

Scientific/Social/Economic Innovative Contribution

- Establishment of secondary use energy storage system from waste batteries.

- Conducting risk, environmental, safety, security, and cost analyses of the methods to be developed and measuring their performance.

- Investigating the use of recycled materials in the production of high-performance electrodes, thereby demonstrating circularity, and exploring the social, environmental and economic benefits.

- Transparency of battery production and tracking using blockchain technologies.

Contribution to the Development of Professional Skills

Through the development of high-tech products and processes throughout the project, professional expertise is gained especially in the fields of autonomous systems, electrochemical, hydrometallurgical processes, electrical and electronics.

Contribution to the Development of Human Resources

By enlightening the articles to be published at the academic level of the project outputs, it supports the increase of qualified labour force together with master's / doctoral studies.

Information about other partners in the project

- ACONDICIONAMIENTO TARRASENSE ASSOCIACION (TECHNALIA) - Spain

- INDUMETAL RECYCLING SA (IND) - Spain

- CENTRO DE EXPERIMENTACIÓN Y SEGURIDAD VIAL MAPFRE S.A. (CESVI) - Spain

- BEEHAZIDPLANET FACTORY SL (BEE) - Spain

- COMANAI S.L (COMA) - Spain

- SIG DE RAEE Y PILAS SOCIEDAD LIMITADA (REC) - Spain

- COMMISSARIAT A L ENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES (CEA) - France

- ORANO Mining (Orano) - France

- RENAULT SAS (REN) - France

- MTB Manufacturing (MTB) - France

- FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V. (IWKS) - Germany

- TECHNISCHE UNIVERSITAET BRAUNSCHWEIG (TUBS) - Germany

- ISLE UTILITIES BV (ISLE) - Netherlands

- MINESPIDER GERMANY GMBH (MINE) - Germany

- POSCO (POSCO) - South Korea

- FORD OTOMOTIV SANAYI ANONIM SIRKETI (FORD) - Turkey

- TORRECID SA (TOR) - Spain

- CENTRE FOR EUROPEAN POLICY STUDIES (CEPS) - Belgium